Drastic Newsletter December 2024

Welcome to the winter 2024 edition of the Drastic project newsletter.

Drastic is a pioneering four-year collaborative project, launched in October 2023 and co-funded by the European Union (EU) via the Built4People Partnership.

Drastic aims to address the untapped potential for decarbonisation and significant transformation within the European built environment via a collection of circular, low carbon, affordable and innovative 'Demonstrator’ projects.

Via its five Demonstrators, combined with improved business models, Drastic aims to pave the way towards a whole-life cycle decarbonisation of EU building stock by 2050.

Working with 23 partners across eight European countries, Drastic aims to showcase varied and innovative solutions to reduce Whole Life Carbon (WLC) and the climate impact of construction across the entire European value chain, while increasing and improving circularity within the built environment.

Latest News

Drastic General Assembly

Project stakeholders gathered at the General Assembly in Merdingen, Germany

Drastic stakeholders gathered in Merdingen, Germany, in November for the project’s General Assembly meeting.

With project partners attending from across Europe, the three-day agenda comprised a mix of collaborative workshops, team activities and invigorating strategic discussions under the theme of digitalisation, including:

- A deep dive on the application of the Drastic guidance framework;

- A peer consultation on the developments and critical points of the Demonstrators;

- A workshop on data collection protocol and technical requirements and specifications for traceability;

- A participatory exploration of circular business models and communication strategies.

As part of the meeting, the project team also had the opportunity to exchange their laptops and pens for hammers and crowbars to experience Drastic partner, Weber Saint-Gobain’s, circular cladding solution (Weber.Therm Circle) first-hand during a circular deconstruction workshop.

Project stakeholders take part in the circular deconstruction workshop led by Weber Saint-Gobain

The activity highlighted the system’s efficiency in enabling quick, clean disassembly of separate materials, contrasting with the wasteful and labour-intensive process of dismantling the business-as-usual (BAU) solution.

Find out more about the Weber.Therm Circle cladding solution in the ‘Meet the Demonstrator’ section below.

The next Drastic General Assembly will be held in Paris in Spring 2025.

Meet the demonstrator

German Demonstrator

Based in Düsseldorf, Drastic’s German Demonstrator aims to address the energy inefficiency of apartment buildings via a circular renovation solution that focuses on thermal insulation systems.

Supported by Drastic partners Weber Saint-Gobain and Saint-Gobain Isover, the German Demonstrator aims to leverage an External Thermal Insulation Composite (ETIC) system specifically designed to reduce a building’s heating-related energy use over a 50-year lifespan.

The Demonstrator aims for its circular insulation system to match the reliability of more conventional market options, making it a promising alternative in Europe’s building insulation market and highlighting the potential of circular construction practices to meet energy efficiency and sustainability goals within the European built environment.

The German Demonstrator’s Weber.Therm Circle system is the first ETIC system designed to be fully dismantled and recycled, allowing thermal insulation to be reused and other components to be processed into aggregates for improved circularity.

To test durability, the project is also constructing mock-up walls exposed to accelerated weathering, assessing the long-term viability of reusing insulation boards.

Read more about Drastic's Demonstrators.

Recent project activities

Progress in work package four (WP4): digital traceability for circular solutions

Project stakeholders gather to discuss WP4

A key Drastic initiative, Work Package 4 (WP4), focuses on rethinking traceability via digital innovation; a process that uses advanced tools to track and assess building materials and processes throughout their lifecycle.

Drastic leverages two innovative platforms from project partners, Madaster and Caala, to support building-level calculations:

- Madaster registers building materials, providing Material Passports that link materials to their location and characteristics for reuse and recycling.

- Caala offers real-time assessments of building designs for environmental and economic performance. Integration with Madaster ensures data flow and alignment with circular principles.

At the product level, Tecnalia leads efforts to define technical requirements and implement traceability systems. These systems align with European regulations, such as the Digital Product Passport and Construction Products Regulation, enabling a unified data framework for stakeholders.

Achievements to date

- Platform interoperability: Progress has been made in integrating Madaster and Caala to provide building-level diagnostics.

- Technical specifications: Tecnalia has outlined frameworks and data requirements for product-level traceability.

- Stakeholder feedback: Input from Drastic’s Demonstrators has helped shape traceability systems to meet practical needs and regulatory demands.

These milestones mark significant progress in transforming traceability practices and ensuring that Drastic’s solutions address modern construction challenges while supporting and further developing circularity within the built environment.

Next steps

WP4 will focus on refining and expanding platform functionalities to strengthen material tracking capabilities and sustainability outcomes.

Planned developments include:

- Integrating advanced tagging technologies, such as (Radio Frequency Identification) RFID and QR codes.

- Utilising AI-driven tools for automatic asset identification and reusability assessment. By addressing these areas, WP4 aims to position Drastic as a leader in sustainable construction, transforming traceability into a tool for innovation, sustainability, and advanced analysis.

Read on below to learn about Tecnalia’s presentation of WP4’s digital platform at Sustainable Places 2024.

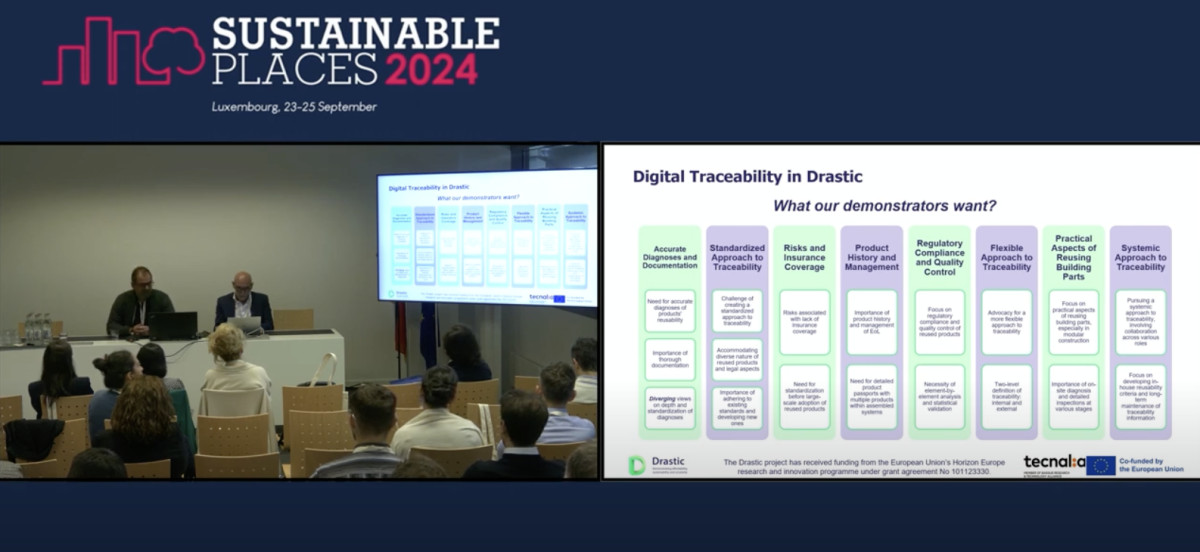

Tecnalia showcases Drastic’s WP4 digital platform at Sustainable Places 2024

Tecnalia’s presentation at Sustainable Places 2024

Drastic’s digital platform was presented by project partner, Tecnalia, at the Sustainable Places 2024 conference, held in Luxembourg. During the “Data Management for Enhanced Built Environment Circularity” workshop, Tecnalia showcased how the platform enhances traceability, sustainability, and quality performance in construction, particularly for re-used building elements.

The platform’s key features include:

- Advanced tagging technologies (e.g., RFID and QR codes) and AI tools.

- Multi-cycle Life Cycle Assessment (M-LCA) and Life Cycle Costing (M-LCC).

The workshop also explored:

- Best practices in digital solutions for construction circularity.

- State-of-the-art tools and roadmaps for sustainable building.

- The critical role of reusing construction components to improve lifecycle performance and enable digital traceability.

Watch a recording of the full workshop here.

Recent events

Drastic presented at Built4People Clustering Event

Built4People Partnership stakeholders gathered at the clustering event

In November, representatives of 30 projects funded under the umbrella of the #Built4People Co-programmed Public-Private Partnership (including Drastic) gathered at CINEA, Belgium, for a special clustering event organised by the Nebula Project.

The funding for these projects sits under the “Efficient, sustainable and inclusive energy use” part of the Horizon Europe Work Programmes for Climate, Energy and Mobility.

As part of proceedings, Michiel Ritzen, head of the competence center on sustainability assessment at project partner, VITO, presented a general overview of Drastic, which prompted group discussions on the following topics:

- How can Drastic learn from previous/other projects and increase impact via collaboration?

- How to get the information of the circular products at the right time to the right person in the market?

- How can Drastic capitalise its key project results?

- How can Drastic find key synergies with other European projects?

Michiel also spoke about some of the challenges Drastic faces, as well as how the project is contributing towards the general objectives of the Built4People Partnership.

Learn more about the Built4People Partnership.

Norwegian Demonstrator tests Drastic product designs via the Ice Box Challenge

Ice installed into one of the mini-houses as the Ice Box Challenge, Oslo

In Oslo, Norway, two of Drastic’s Norwegian Demonstrator partners, Produktif and Omtre, participated in the Ice Box Challenge across May and June.

Produktif, the event co-organiser, invited Omtre to take part in the challenge to showcase the possibilities of using reclaimed waste wood as a cladding element.

The aim of the challenge was to demonstrate the benefits of passive house construction by building two small units known as ‘mini-houses’; one using the Norwegian national code of construction and the other using the Passive House standard (the world‘s leading standard in energy-efficient construction).

On 19 May, ice blocks weighing one tonne were installed in each mini-house, where they were to remain untouched for a whole calendar month. On 19 June, Her Royal Highness Princess Astrid of Belgium re-opened both mini-house constructions, revealing incredible results.

After 33 days, the Passive House constructed unit still contained 150 kg of ice, while the ice installed into the unit built under the standard Norwegian national code of construction had completely melted within just 11 days.

Via the Ice Box Challenge, Produktif and Omtre were able to exemplify the potential of design for reuse by reusing wood as a cladding element, with the mini-house operating under the Passive House standard being clad with waste wood from a new construction site.

As well as this, the passive mini-house demonstrated the aesthetic potential of 120 old Norwegian barn cladding planks, repurposed for a second life cycle within the mini-house’s circular design.

In close collaboration with Drastic, Produktif and Omtre were able to test their products and design ideas via the Ice Box Challenge, prior to relevant work commencing on their Drastic Demonstrator project, aiding the development of the temporary shed as part of the Norwegian Drastic Demonstrator.

Produktif also used this opportunity to further test its Design for Assembly and Disassembly (DFAD) methodology, and to apply its unique ‘C-Joint’ system to the Passive House model.

Learn more about Drastic’s Norwegian Demonstrator.